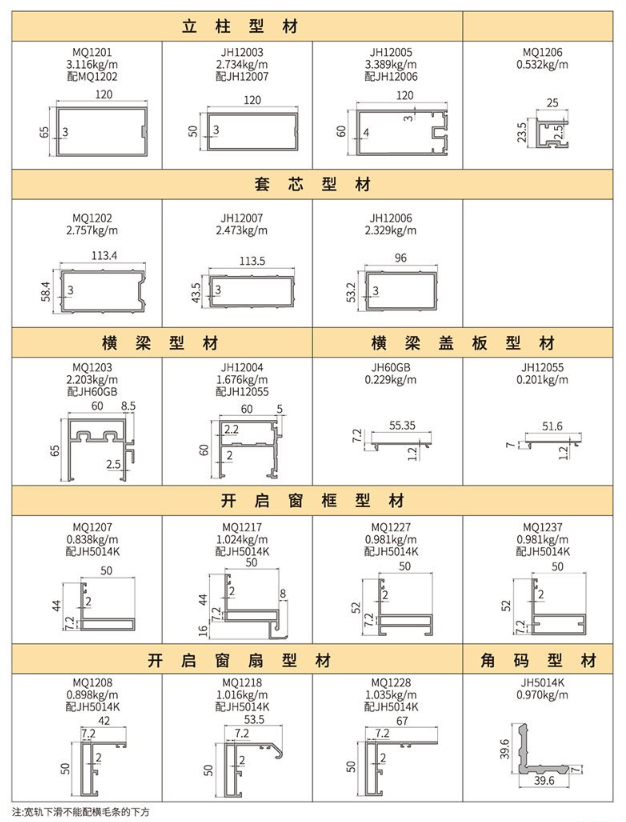

Weyalu aluminium extrusion factory aluminium curtain wall customized aluminium profile energy saving system powder coating anodizing

With high-quality anodizing and powder coating, aluminium profile are highly resistant to corrosion, fading, and wear, ensuring a long-lasting, maintenance-free solution.

Length :

5.8 M, 6.0M or CustomizedAlloy :

6061 6063 6060 6351 6005 6082 5050Temper :

T3 - T8Standard :

GB/T3190-2008 Chinese StandardOEM/ODM service :

Customized design,Technology supportDelivery :

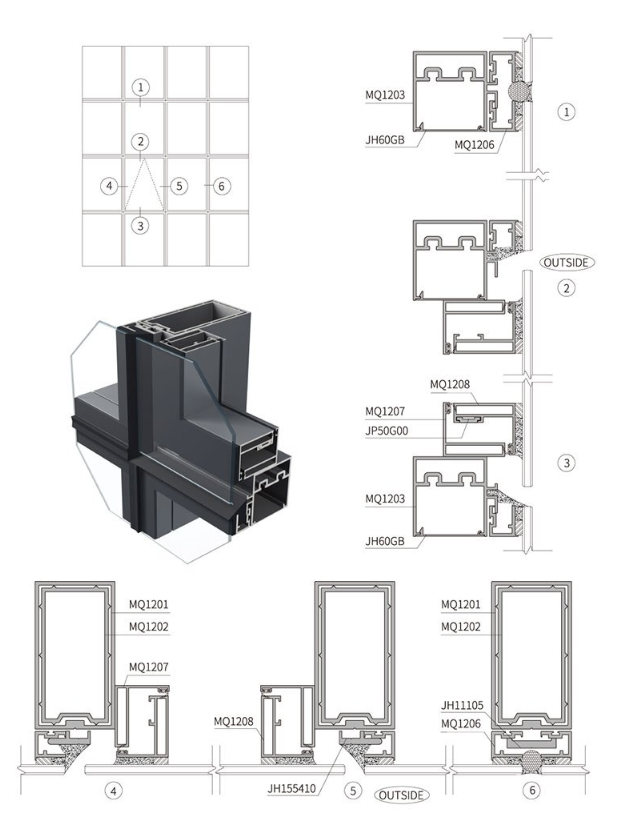

5-7 days to cut new molds, 10-15 days to finish productionOur advanced aluminium profile system combines innovation and sustainability to meet your specific needs. Our aluminium profiles are designed with energy savings in mind. The system incorporates thermal breaks and insulating materials, ensuring excellent thermal performance, which reduces heat transfer and saves on heating and cooling costs. Tailor-made to your exact specifications, our aluminium profiles offer limitless design possibilities. Whether it's for windows, doors, curtain walls, or any other architectural element, we can create profiles that match your unique vision.

|

Product range |

Customized aluminium profiles , completed aluminium window, aluminium doors, Aluminium profiles for window and door, kitech, decoration, and industrial usage aluminium profiles |

|

Length |

5.8 M, 6.0M or Customized |

|

Alloy |

6061 6063 6060 6351 6005 6082 5050 |

|

Temper |

T3 - T8 |

|

Surface treatment |

Powder coating: Customized any color |

|

Anodizing : Silver, Bronze, Black, Champagne, Golden , Titanium |

|

|

Wooden color: Customized any wooden color |

|

|

Chemical polishing, Sanding blast, Brush texture etc. |

|

|

Deep Processing |

Drilling, Bending, Cutting, Welding, CNC processing. |

|

Standard |

GB/T3190-2008 Chinese Standard |

|

General Package |

1, Stick the protective film on the surface of profile. Numbers of profiles wrapped by shrink film. 2. Special package: same as customer’s requirement. |

|

Delivery |

15-20 days after the order details confirmed. |

OUR ADVANTAGE

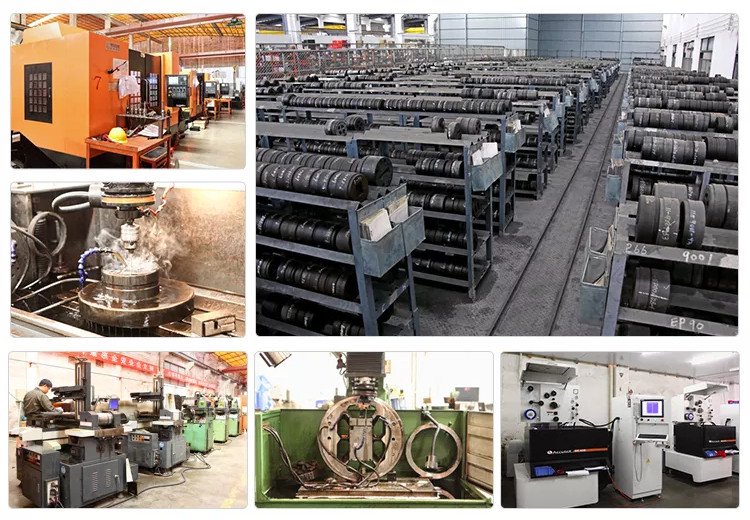

1. Die workshop

Our R&D team has over 50 experienced staffs, quick action to die design, evaluation, cutting. We have our own die workshop to finish quickly, 5-7 days to finish die design and cutting.

2. Extrusion system

Equipped with 23 extrusion production lines, including 600 tons to 5000 tons press machine imported from Japan, Italy and Taiwan. The annual production of extrusion machine line is beyond 120,000 tons.

3. Electrophoresis & oxidation system

Two automatic horizontal oxidation production lines, which imported from German and Korea.

4. Powder coating system

Equipped two powder coating lines. One is a vertical line, another is the horizontal line. Using world's famous Aksu powder Dupont Powder. Etc.

More Aluminum Profiles You Will Like

Could you share your business card with us or leave your email address so that we can share new prices conveniently?

FOR MORE THAN 25 YEARS, WEYALU Aluminium Co., Ltd has built a good reputation as one of Chinese leading manufacturer of aluminium extrusion since 1994, located in Foshan,Guangodng, China. Through decade years development, we have three production basement now, 23 extrusion lines and all finish equipment, such as vertical powder coating line, Anodizing line, Wooden grain line, CNC machines. The annual production capacity is more than 120,000 Tons.

|

||

| We are one of the earliest ones to pass and carry out IsO 9001: 2008 Standard, IsO 14001 and IsO 18001 Certificates, and obtained honors. | Not only the modern equipment in our industry, but also has 200 senior technical managers and 1000 loya workers to build high-tech enterprise. |

Our products are well sold in Australia, Singapore, Europe, East Asia, Middle East and Africa.

|

Mould Workshop

Extrusion Workshop

WEYALU aluminum is equipped with 23 extrusion production lines, including 5000-tons press extrusion machine imported from Japan, 1800-tons press extrusion machines imported from Taiwan. And cooling system and automatic double tractor imported from Italy, which improve the production capacity and reduce the labour cost. The annual production of extrusion machine line is beyond 120,000 tons.

Surface Treatment Workshop

The powder coating equipment is from Britain Eluda Co, which is the most high-tech equipment and enable to reach international standard. WEYALU's profiles provide all kinds of powder coating colour to large-scale communities, residential regions and all kinds of building projects. The products also attain" Green Building Material" honour.

We have 2 advance powder coating lines, one is horizontal production line, the other is the vertical production line. The maximum production capacity of vertical line can reach 3000 tons monthly. Meanwhile, we imported two automatic anodize and electrophoresis production line from abroad.